KVK Number: 98122312 Phone:+31 6 2889 0071 Email: fluxontechnology.bv@gmail.com

Production Line

Our factory’s production lines feature advanced equipment, enabling efficient production processes. This efficiency reduces production time, operating costs, and errors. We are committed to ensuring the timely and safe delivery of reliable, high-quality products through our professional work ethic.

GKG G5

Solder Paste Printer

Solder Paste Printer is the first core process equipment of SMT production line. Its main function is to print solder paste accurately onto the pad position on PCB to prepare for the subsequent placement of components by SMT machine.

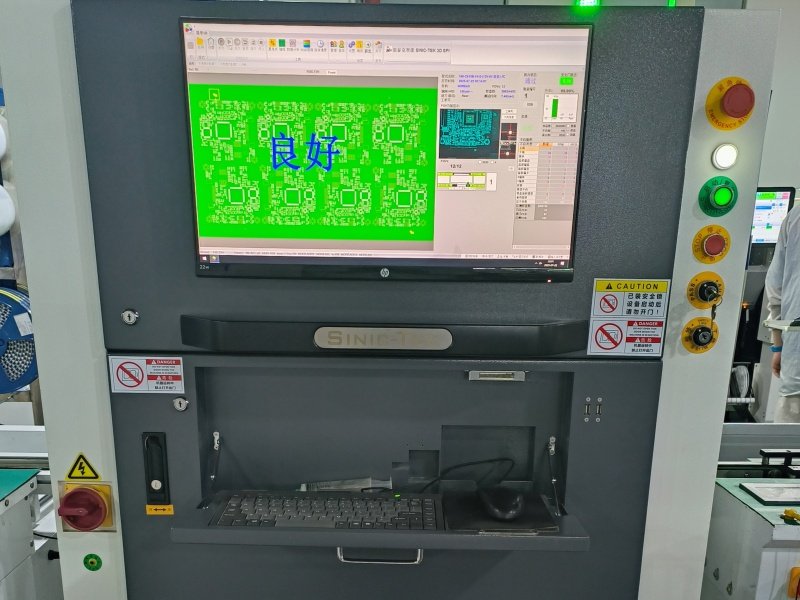

SINIC-TEK

Solder Paste Inspection

Solder Paste Inspection equipment is used in the SMT process before the placement machine to perform 100% online inspection of solder paste quality after solder paste printing to ensure reliable solder joint quality.

Hanwha SM-471/481

Fast Chip Shooter

This high-performance SMT component placement machine places electronic components onto PCBs (Printed Circuit Boards) at high speed and with high precision. It performs "pick and place" functions on production lines.

JTE-1000

SMT Reflow Oven

Reflow oven is a device used in SMT production to heat the solder paste and components mounted on a PCB, melting the solder paste and firmly soldering it to the component pins.

ALeader ALD7120

AOI equipment

ALeader ALD7120 is an advanced offline high-precision AOI equipment. Its main function is to automatically detect components and soldering defects on PCB boards through optical technology to ensure product quality.

Scienscope View X1800

X-ray inspection equipment

Scienscope View X1800 is used for critical defect analysis in SMT processes. It complements internal defects that AOI cannot directly see, helping to eliminate hidden soldering issues such as BGA voids or poor pin contact.

Get In Touch With Us

Our professional team will contact you as soon as possible to meet your needs.

- Price reply with in 12 hours

- An urgent order as fast as 24 hours

- 3 years warranty

- ISO9001/ISO13485/IATF16949/UL/ROHS certificated