KVK Number: 98122312 Phone:+31 6 2889 0071 Email: fluxontechnology.bv@gmail.com

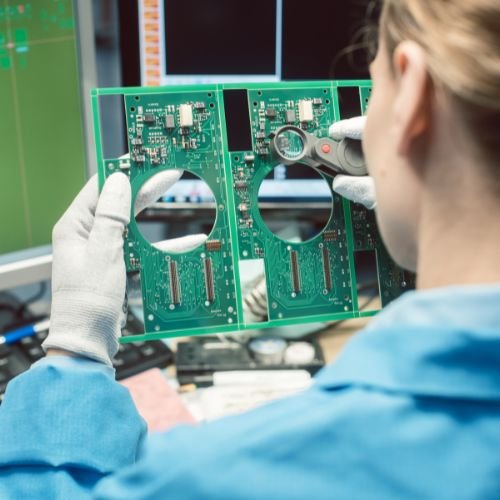

The printed circuit board sits at the heart of modern electronics. It links components and routes signals so devices and systems run reliably.

Across consumer, medical, industrial, automotive, aerospace, and LED lighting, pcbs make products work. Advances in materials and manufacturing let designers pack more function into smaller boards today.

Types range from single- and double-layer to multi-layer, plus rigid, flex, and rigid‑flex solutions. Each board balances component choices, costs, and performance to meet industry needs.

Quality in assembly and equipment matters for safety and durability in regulated sectors. In the following lists, we’ll map pcb applications to concrete devices like medical monitors, industrial inverters, and automotive ADAS.

This short guide will help readers find practical, present-day insights on how printed circuit boards are used across products and systems, and which types best fit specific needs.

What are the applications of PCBA today?

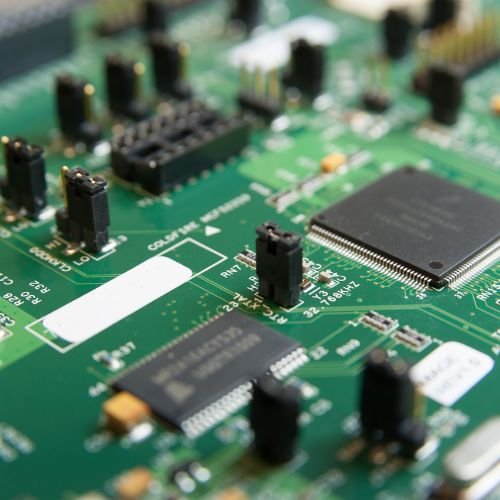

From simple chargers to flight controls, pcbs bring components together into functioning equipment. Printed circuit boards use non‑conductive substrates layered with copper to route power and signals. Designers pick single, double, or multi‑layer stacks based on density and cost.

Single‑sided boards suit basic, high‑volume products. Double‑sided boards add vias for tighter routing. Multi‑layer boards enable compact, high‑speed systems and can exceed fifty layers for complex equipment.

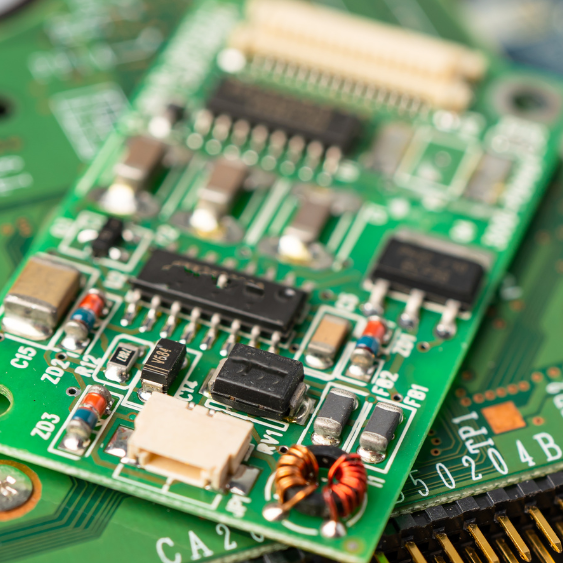

Flexible and rigid‑flex pcb formats solve space, weight, and vibration limits in wearables, automotive, and aerospace devices. Material choices and stackup meet thermal and regulatory requirements.

Manufacturing volume, yield, and pcb assembly constraints shape which boards are economical today. Component selection, signal integrity, and thermal paths drive design choices that affect EMC and product life.

| Board Type | When to Use | Typical Industries |

|---|---|---|

| Single‑sided | Low cost, simple routing | Consumer, basic appliances |

| Double‑sided | Moderate density, vias allowed | Industrial controls, home devices |

| Multi‑layer / Rigid‑flex | High density, compact or moving parts | Automotive, medical, aerospace |

- Match board types to product scope early in design.

- Plan for manufacturing and assembly to meet reliability targets.

- Choose materials for thermal, EMC, and lifecycle needs.

Consumer electronics: PCs, smartphones, and home appliances

Consumer gadgets today pack dense circuitry to squeeze powerful features into tiny shells. Designers choose layer counts, materials, and layout to hit cost and thermal targets while delivering fast wireless and display features.

Mobile devices and wearables

Smartphones, tablets, and smartwatches often use a compact circuit board with careful routing to support antennas, batteries, and chips in tight enclosures. Controlled impedance and stackup planning help radios and screens perform reliably.

Computer electronics

Desktops, laptops, and motherboards balance thermal design, power delivery, and battery life. High-speed I/O needs precise pcb traces and sparse component placement on multi-layer boards to avoid signal loss.

Recording and entertainment systems

TVs, game consoles, cameras, and microphones pack signal-processing components to handle audio and video streams. Quality parts and board layout reduce noise and improve picture and sound.

Smart home appliances and cost control

Microwaves, refrigerators, and coffee makers now include pcbs used for control, sensors, and connectivity. Mass-market products push manufacturing efficiency, testing, and pcb assembly standards to ensure safe, consistent products worldwide.

- Design, sourcing, and safety standards guide materials and production flow for this industry.

Medical devices and healthcare systems powered by PCB assembly

In healthcare, small, reliable circuit assemblies make life-saving monitoring and therapy possible. Medical products depend on high-density and flexible boards to meet tight size and performance needs.

Patient monitors: heart rate, blood pressure, and glucose monitoring

pcbs and assemblies drive continuous monitoring with precision sensors and signal conditioning. Designs focus on uptime, low noise, and clear telemetry for accurate heart and pressure readouts.

Scanning and imaging: CT, MRI, and ultrasonic equipment

Miniaturized printed circuit board layouts and shielding materials help preserve signal integrity in scanners. High-density interconnects support fast data paths and tight tolerances for images.

Electronic control systems: infusion pumps and flow control

Control systems require redundancy, precise timing, and validated firmware to keep dosing accurate. Robust traceability and strict testing back every release and build.

Implantable and internal devices: pacemakers and life-support electronics

Implantable products use compact pcb designs and biocompatible materials. Manufacturing and assembly must meet sterilization and long-term lifecycle support for safe implants.

Scientific instrumentation: microscopes, photometers, and lab control systems

Research equipment needs stable circuits and low-noise layouts for repeatable results. HDI and flexible board types are common where space and reliability matter most.

“Medical boards must balance miniaturization with traceability and rigorous testing to protect patient safety.”

High standards in the medical industry mean components, materials, and assembly processes follow strict documentation and validation. That elevated reliability sets medical products apart from general consumer devices.

Industrial equipment: printed circuit boards for harsh conditions

Industrial circuit assemblies must survive chemicals, vibration, and continuous duty on factory floors. Designs stress durability, thermal performance, and clearances to meet those needs.

Factory equipment and tools

Drills, presses, and automated machinery demand boards that handle high currents and mechanical shock. Designers use thick copper and reinforced substrates to carry motor drive loads.

Reinforced stackups reduce warpage and protect components during heavy use.

Measuring and control gear

Pressure and temperature instruments rely on stable reference circuits and noise mitigation. High-quality pcbs and careful grounding keep readings steady under interference.

Modular board layouts often allow rapid field swaps and faster maintenance cycles.

Power and energy equipment

Inverters, solar cogeneration, and battery chargers use wide copper pours and thermal vias to move heat away from power stages. Multi-layer and rigid‑flex types can cut wiring and simplify installations.

Conformal coatings, sealed enclosures, and stringent testing help boards resist contaminants. Predictive sensors on the board feed PLCs and SCADA for condition-based maintenance.

- Robust stackups prioritize creepage/clearance and thermal paths.

- Assembly and parts must withstand shock, vibration, and factory contaminants.

- Compliance and documentation link design to safe field service and longer service intervals.

Automotive electronics: ADAS, control systems, and in‑vehicle infotainment

Modern vehicles rely on compact electronic boards to run safety, power, and entertainment features.

Surrounding monitors and ADAS

High-frequency radar and camera modules use pcbs with RF materials and controlled impedance routing. This keeps timing accurate and reduces signal loss in collision avoidance and blind-spot detection.

Engine and powertrain control

Engine control systems need rugged pcb layouts to manage fuel, ignition, and energy flow. Robust components and thermal vias help the control systems meet durability and emission targets.

Navigation and GPS

Navigation devices pair gps radios with on-board computing. Designers focus on EMI control and resilient power architectures so route planning stays reliable on the road.

Infotainment and connected dashboards

Infotainment boards enable audio, video, and phone connectivity across vehicle networks like CAN and Ethernet. Modular designs speed repairs and support over-the-air updates.

| Feature | Why it matters | Typical board type |

|---|---|---|

| Radar/Cameras | High-speed signaling, shielding | RF pcbs, multi-layer |

| Powertrain Control | Heat, vibration, high current | Thick-copper, rigid |

| Infotainment/GPS | EMI control, connectivity | Rigid-flex |

Design tradeoffs balance reliability, cost, and performance under harsh conditions through shielding, thermal management, and flexible circuits chosen to reduce weight and absorb vibration.

Aerospace and aviation: reliable circuit boards under extreme stress

Aircraft and satellites rely on a printed circuit board that stays precise while cutting mass. Lightweight layouts and strict trace control keep avionics working through turbulence and launch loads.

Monitoring sensors in flight-critical areas

Accelerometers, pressure sensors, torque gauges, and force sensors mount to small assemblies near engines and cockpits. These sensor devices use high-accuracy traces and calibrated components to deliver trusted readings.

Flight testing and validation systems

Flight-test equipment captures structural strain and vibration with tight timing. Engineers ruggedize boards and connectors so telemetry survives shock, thermal cycling, and high G events.

Lightweight flexible solutions and materials

Flexible pcb designs lower harness weight and cut failure points. This way, wiring mass falls and vibration-induced breaks drop sharply.

| Role | Design focus | Typical solution |

|---|---|---|

| Sensor modules | Precision, low mass | HDI rigid or thin flex |

| Flight-test recorders | Timing accuracy, ruggedness | Multi-layer rigid with shielding |

| Avionics control | Redundancy, EMI protection | Redundant boards, metalized shields |

- Materials and stackups resist outgassing and wide temperature swings.

- Shielding and grounding strategies protect critical circuit function from interference.

- Documentation, traceability, and redundant systems meet strict certification and mission-assurance needs.

In the aerospace industry, design choices set the bar for quality. These pcb applications must survive radiation, shock, and sustained thermal cycles while keeping mission data accurate.

Lighting and LED-based devices using printed circuit boards

High‑output LED systems rely on smart board design to manage heat and ensure long life. Aluminum-backed pcbs move heat away from diodes so fixtures run cooler and last longer.

Telecommunications indicators and displays

Telecom panels and status displays often use metal-core boards to cut maintenance. Better thermal spread keeps LEDs stable under long run times.

Automotive lighting and dash displays

Headlights, brake lights, and instrument clusters need consistent color and brightness across temperature swings. Rigid metal boards maintain uniform thermal profiles and reduce color shift.

Desktop and laptop indicators

Computers and peripheral LEDs operate in tight enclosures. Aluminum substrates help protect diode junctions when ventilation is limited.

Medical, residential, and storefront lighting

Surgical lamps and smart signage require steady output and long service life. Proper circuit routing and substrate choice lower fixture temperature and extend lumen maintenance.

| Use case | Why metal-backed helps | Key design focus |

|---|---|---|

| Telecom displays | Improved thermal spread, less downtime | Uniform heat path, reliable solder joints |

| Automotive lights | Stable color under heat | Thermal vias and controlled traces |

| Medical/storefront | Long life and steady output | Material flatness, solder alloy choice |

Assembly choices like substrate flatness and solder alloy influence LED junction temperature and lifetime.

“Thermal design at the board level often replaces bulk heat sinks and cuts both size and cost.”

Conclusion

Good circuit layout and assembly turn designs into dependable systems across industries.

Across consumer electronics, industrial equipment, medical devices, and aerospace, pcbs and pcb choices shape how products perform under pressure, vibration, air travel, and thermal stress.

When board types, components, and assembly practices align to clear requirements up front, teams cut risk, speed development, and lower total cost. A well‑designed board can improve serviceability, enable updates, and simplify computer hardware integration.

Choose verified parts, follow proven design rules, and require certification so medical and aerospace gear keep signal integrity while handling pressure and temperature extremes. Map your industry needs to the right types and architectures to meet safety, cost, and performance targets.