KVK Number: 98122312 Phone:+31 6 2889 0071 Email: fluxontechnology.bv@gmail.com

PCB Assembly Capacities

Fluxon Technology BV offers a full range of PCB assembly services, covering both rigid and flexible circuit boards. We source components directly from authorized distributors such as Digikey, Mouser, and Avnet to ensure quality and maintain a constant inventory. Our dedicated team uses state-of-the-art equipment to ensure you receive the highest quality, reliable, and durable PCB assembly products.

Items | Capabilities |

Placer Speed | 13,200,000 chips/day |

Bare Board Size | 0.2 x 0.2 inches - 20 x 20 inches/ 22*47.5 inches |

Minimum SMD Component | 01005 |

Minimum BGA Pitch | 0.25mm |

Maximum Components | 50*150mm |

Assembly Type | SMT, THT, Mixed assembly |

Component Package | Reels, Cut Tape, Tube, Tray, Loose Parts |

PCB Assembly Process

A typical PCB assembly process consists of the following steps

Preparation before PCBA

Verify that all electronic components fully match the customer’s BOM and ensure that materials meet their specifications.

- DFA Checks

- Component Incoming Inspection

SMT & THT Assembly

Mounting of surface-mount components and through-hole components are completed after this stage.

- Fabricating the SMT Stencils

- Solder Paste Printing

- Solder Pasting Inspection

- SMD Components Placement

- Reflow Soldering

- AOI/X-Ray Inspection

- Through-Hole Component Insertion

Inspection and Testing

We strictly follow international and customer standards for quality control to ensure that every delivery meets high standards.

- AOI/X-Ray Inspection

- Function Testing

- Final Inspection and Testing

- Cleaning and Drying

- Package and Delivery

PCB Assembly Equipments

We use state-of-the-art equipment to provide you with faster assembly times, higher precision and lower costs

Loading Machine

GKG G5

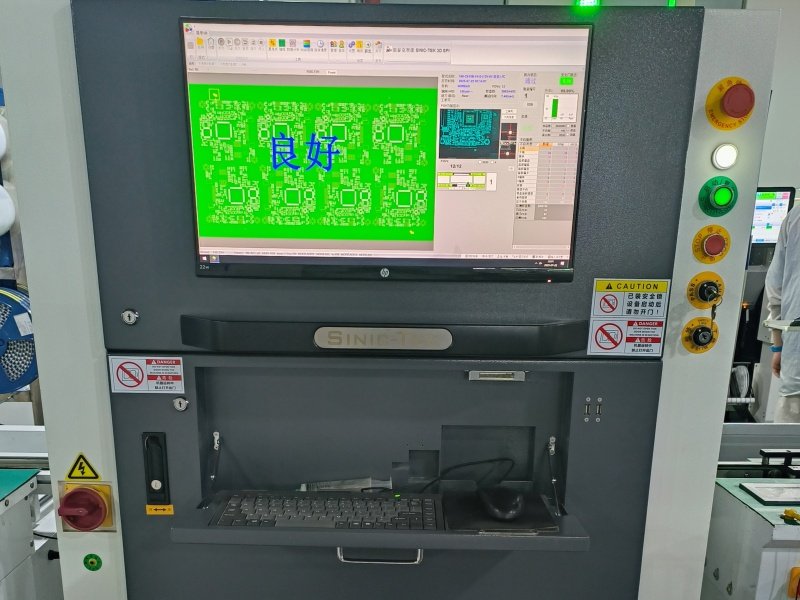

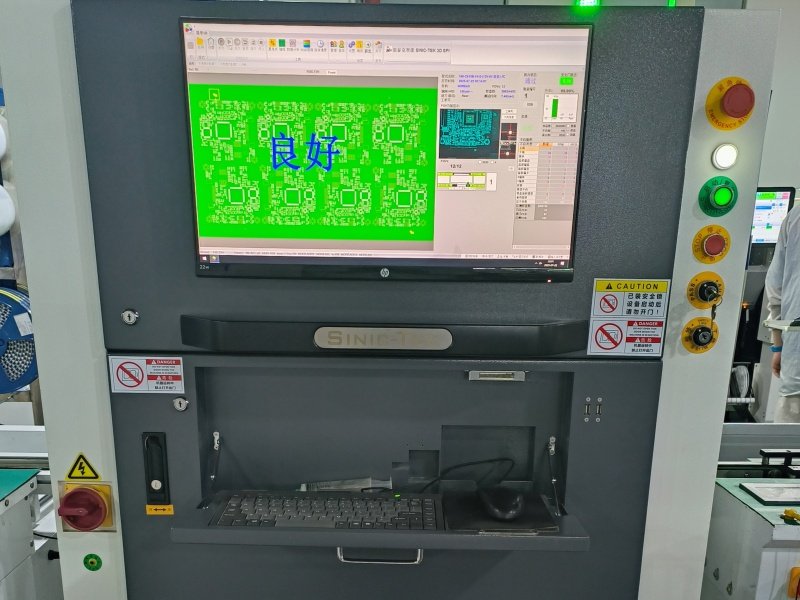

SINIC-TEK

SAM-471

SAM-481

JTE-1000

ALD7120

View x1800

PCB Assembly Quality Control

We deliver on our promise of quality assurance. We continuously perform various checks during the production process, in accordance with IPC A-610-F. These meticulous inspections, often using high-tech automation, ensure the continued high quality of your products.

SINIC-TEK

ALeader ALD7120

Scienscope View X1800

Get In Touch With Us

Our professional team will contact you as soon as possible to meet your needs.

- Price reply with in 12 hours

- An urgent order as fast as 24 hours

- 3 years warranty

- ISO9001/ISO13485/IATF16949/UL/ROHS certificated