KVK Number: 98122312 Phone:+31 6 2889 0071 Email: fluxontechnology.bv@gmail.com

Quality Control

We deliver on our promise of quality assurance. We continuously perform various checks during the production process, in accordance with IPC A-610-F. These meticulous inspections, often using high-tech automation, ensure the continued high quality of your products.

Reliable Raw Material

We select well-known brand raw material suppliers in the PCB industry to ensure quality assurance. We use high-quality materials to manufacture high-quality PCBs.

Raw Material Inspection

All components and parts must undergo a strict incoming inspection and quality control process before entering our warehouse.

Certifications

We have advanced industry and international PCB certifications to verify our extremely stringent standards.

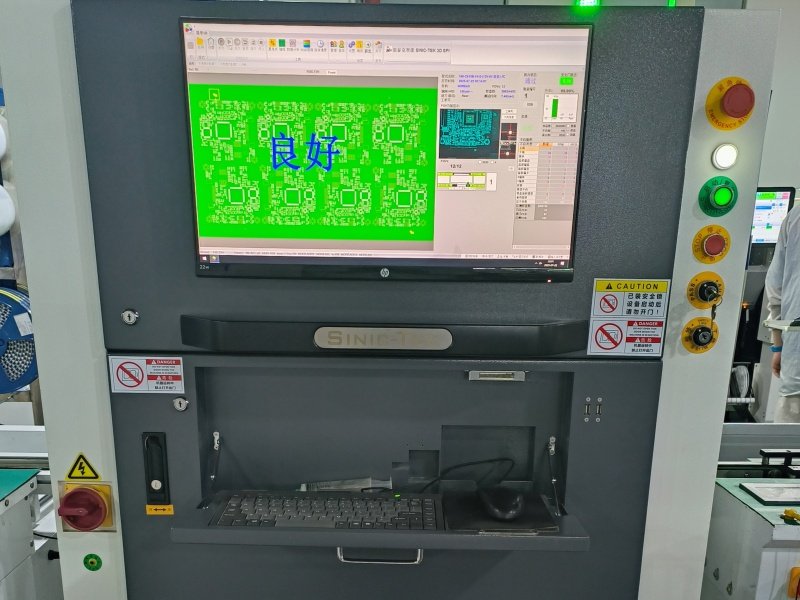

Automatic Optical Inspection

AOI uses high-speed cameras and algorithms to automatically inspect products such as PCBs, quickly identifying defects such as missing components and solder joints.

Electrical Test

Electrical testing mainly checks each unassembled circuit board for short circuits, open circuits, resistance, capacitance and other basic electrical characteristics.

Functionele Test

By thoroughly testing product functionality, we can discover and correct issues that other forms of testing might not reveal, ensuring proper functionality.

Testing Equipment

SINIC-TEK

ALeader ALD7120

Scienscope View X1800

Get In Touch With Us

Our professional team will contact you as soon as possible to meet your needs.

- Price reply with in 12 hours

- An urgent order as fast as 24 hours

- 3 years warranty

- ISO9001/ISO13485/IATF16949/UL/ROHS certificated